Australian-listed Variscan Mines says a high-tech survey of historical underground workings at Udias in northern Spain has helped it generate the first accurate geospatial model of the former high-grade zinc mine.

Variscan CEO Stewart Dickson said the 3D survey using advanced Swedish surveying equipment and software “significantly improves our understanding” of Udias, a core piece of what the junior describes as its advanced-stage Novales-Udias zinc-lead project about 30km south-west of Santander and within “trucking distance” of Glencore’s major San Juan de Nieva zinc smelter.

“Having a 3D survey to supplement our underground access is very valuable,” Dickson said.

“We can now see, visualise, model and access underground mineralisation, physically and digitally.

“Advancing our understanding of Udias is very valuable as we have long been confident that [it] has significant potential to grow the overall Novales-Udias project significantly. Drilling will continue at Udias to explore, define new zones of mineralisation and seek to link up with our existing high-grade mineral resource estimate.

“Our maiden drilling has already delivered excellent high-grade results.”

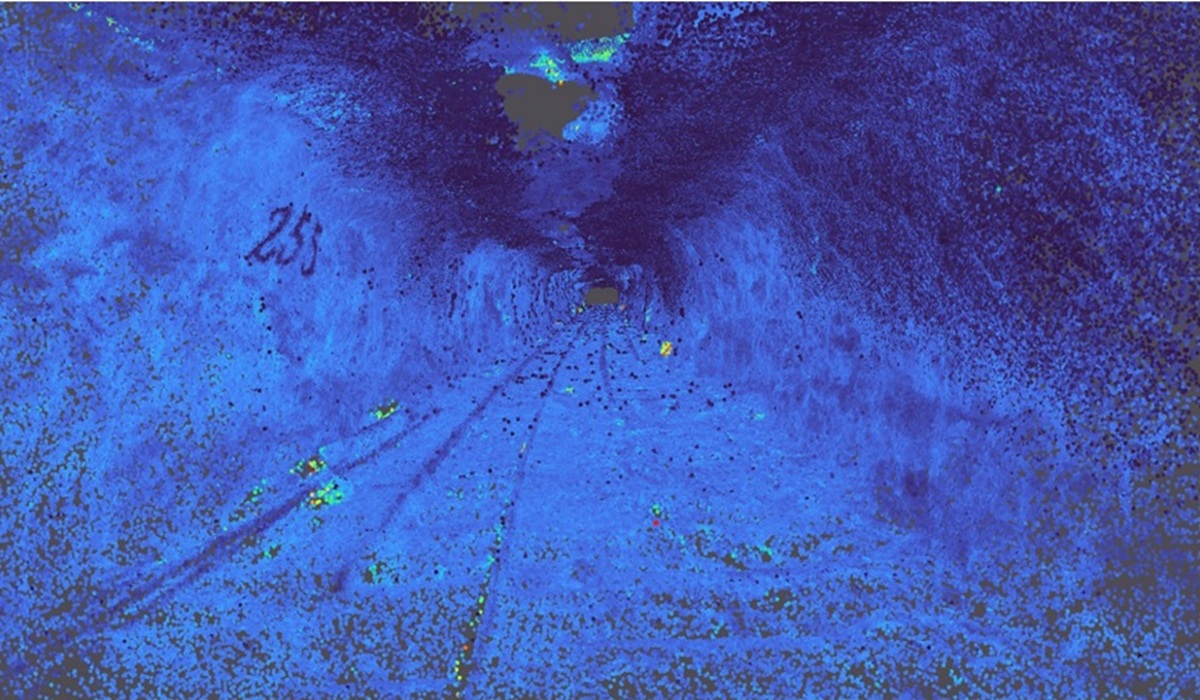

Underground surveying with mobile simultaneous localisation and mapping (SLAM) 3D laser scanning technology showed more than 7500m of historical underground development across six levels and “confirmed multiple extensions of high-grade zinc mineralisation”, according to Variscan.

“The survey demonstrates that the Udias and San Jose mines are part of a single, continuous mineral system,” it said.

Data from the Satlab Geosolutions SLAM scanner was processed with the Swedish manufacturer’s SatPoint PC v1.2.4 software, designed to handle dense point clouds. Variscan says this enabled the generation of 3D models for integration into Seequent Leapfrog Geo software.

The 3D mine model integrates historical drilling, face sampling data and recent exploration results. Variscan said it would inform future drill targeting, mine planning and resource updates.