A new generation of smarter, automated mineral drilling rigs is set to deliver better logistics, safety, environmental and targeting outcomes for miners. But the industry might only be getting a glimpse now of what the future of drilling will look like in 10 years, according to a panel of experts.

That’s mainly because AI is just starting to influence drill program planning based on its knowledge of rocks, rigs, regulations and reporting. Its role as co-pilot on the drills of the future is going to be profound when this awareness develops and can drive and optimise improving automation and digital platforms.

Lima, Peru, based Rio Tinto project coordinator Luis Roble and veteran Boart Longyear commercial drilling services vice-president Jimmy Barrieau joined Imdex digital and orebody knowledge chief Michelle Carey on a webinar hosted by Krux Analytics founder and CEO, Jody Conrad. Krux, part of Imdex, developed drill-rig operations management software used by many contractors and miners, including Rio Tinto and Boart Longyear.

Boart is the world’s largest mineral drilling contractor and also a manufacturer and supplier of drill rigs and consumables.

Iron ore and copper major Rio Tinto spends about US$250 million a year on greenfield mineral exploration.

Australian-based Imdex is a leading global supplier of drilling consumables that has built a circa-US$200 million-a-year sensor and software business.

Barrieau and Roble said a technological mineral drilling age was already delivering safety, environmental and cost gains. More rapid technology-led advances were in prospect and were needed, they said, partly due to the industry’s shrinking skills funnel. Barrieau said without acceptable safety and environmental performance levels, “you’re not going to have a business very long in the next era of mining”.

He thinks the global mineral drill rig fleet will be at least 50% “fully autonomous and AI powered” in a decade.

“It’s going to be a totally different environment in 10 years, in my opinion,” he said.

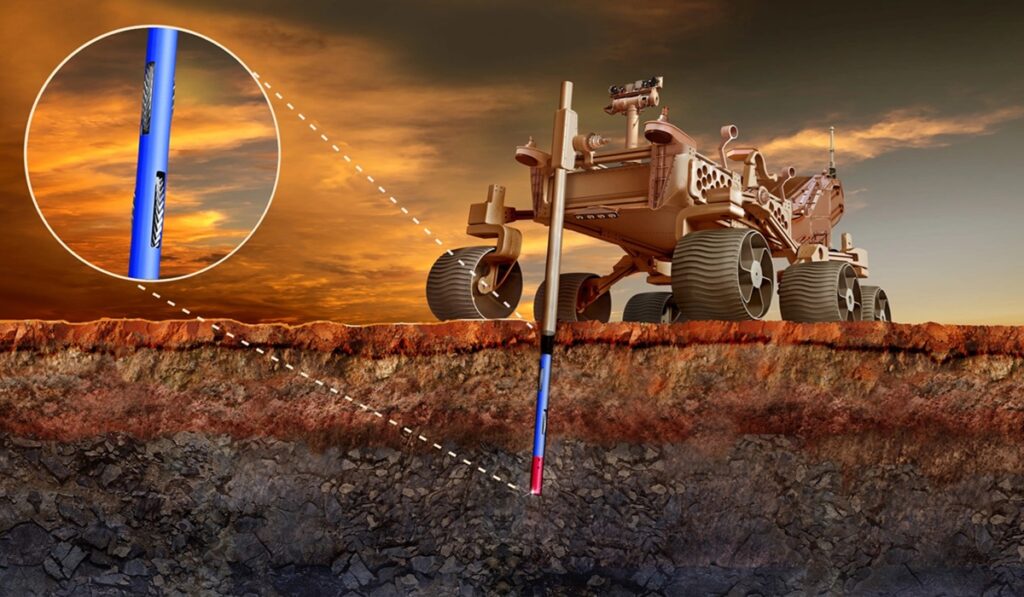

Carey agreed: “I think potentially it’s full autonomy, too. Why can’t the rocks speak directly to the drill rigs? Sensors can tell the drill rigs directly what the rocks are and what they should do next.”

While the picture the industry projects for future employment prospects for drillers and support personnel is fuzzy, to say the least – 100% safety equals zero human entry in hazardous work environments? – the experts say battery-powered robot drills will undoubtedly be cheaper to run and open up new opportunities to drill in logistically problematic locations.

Barrieau said the pending commercial introduction of an AI-assisted robotic rig could be a game-changer.

“We’re ready to deploy what we’re calling our LMR 110,” he said.

“This is the Longyear modular robotic rig, which will operate with AI and will drill itself. There’ll be no human interface whatsoever. We’ve successfully drilled underground in Australia with this rig over 7000 metres.

“Boart Longyear drilling services will bring this to market this year and we’re planning to scale up to have 30 in the market over the next few years.

“This is completely autonomous underground diamond drilling and we believe it’s a true change to the industry. It’s what the industry needs, and it’ll be the future of drilling.

“We [also] have visions of this on surface, [for] heli-portable work, for example. We drop the rig off, it anchors itself, it drills off a magazine of 100 tubes; all the while perhaps connected to Starlink, telling you everything you need to know … All of your data, your metrics and perhaps in-hole geophysics as well, directly communicated from the rig into the cloud and interpreted from an AI perspective.

“So the future’s here, it’s just scaling and getting the right investment and partnership from our global client base.”

Roble said while Rio Tinto, and other miners, were waiting for suppliers such as Boart to bring it a commercial product, he could see the path forward for AI to match the performance of today’s best drillers.

“That driller has their own AI, which is what I call experience,” he said. “Based on the experience the driller can decide what to do according to what the problem is.

“If we get back to the AI system, the experience is basically the data. The question is, do we have enough data to avoid having an expert drilling on site? That’s something that we need to define in the near future.

“Another big challenge that I can see is that every single rock [and] every single formation has their own way to be drilled … and that is where the big data comes in. The software doing all these studies, statistics, math: by using big data we can have the answers on how to drill that specific rock [but] it is a big challenge.

“I don’t know if we have enough data now to put away one driller from the site, but I think that is the future.”

Carey said: “I think we have all of the pieces of the puzzle in terms of sensors that collect rock properties today. We actually do have AI that takes that sensor data and turns it into rock properties. So how do you actually use that to start to create some of these real-time loops [connecting rocks and drillers]?

“Real-time decision making is something we’ve been looking to achieve for a long time.

‘We see some of it now around simple use cases [such as] adjusting the direction of the drill hole.

“But I think creating these real-time decision loops around the rock is … the connectivity between the two worlds where we’re really looking to see some additional disruption and change.”

Barrieau said drill fleet optimisation for carbon emission, water-use and surface footprint reduction remained priorities for the contractor and its mining client base. All of this opened doors to cost and productivity benefits that could be unlocked by greater application of available technology.

“We’re seeing an increasing demand for directional drilling programs, where you have one pad, rather than multiple pads on surface,” he said.

“We can access the orebody by directionally steering the drill bit into the targets that the geologists want to see. So, reducing the surface footprint, reducing all of the emissions involved in moving those rigs multiple times to multiple locations and [using less] water where you’ve got one hole and you’re continuously recirculating water at the one location.”